EV ADDITIVES

Optimizing Grease Performance for Sustainability and the Growing EV Market

SOURCE | IPAC

A

lthough the rate of transition to Electric Vehicles (EV) from the Internal Combustion Engine (ICE) is hard to pin down, the increasing penetration of the market with EV is inevitable. This transition will have a sizeable impact on the future of lubrication, but a key area that will remain vital regardless is that of grease. In the case of the EV, with the plethora of electrical motors and circuits, choosing the right grease will be more important. Couple this transition to EV with the increasing focus on sustainability; and selecting the right grease additive becomes more critical. While Extreme Pressure (EP) and AntiWear (AW) protection will remain a focus, delivery of superb corrosion protection, particularly yellow metal protection will become increasingly paramount.

To this end, there are significant efforts in the lubricant industry to develop tests and materials better suited for EV circuits and devices. For instance, the SAE 3200 standard which establishes key tests and protocols for testing thermal and electrical properties such as conductivity, oxidation and corrosion. The Wire Corrosion Test (WCT) and the Conductivity Deposit Test (CDT) are two such tests that are becoming increasingly key for electrified drivetrains, OEMs and lubricant suppliers who are utilizing these tests to verify the performance of lubricants and greases.

>>With the increasing penetration of EVs in the market, this transition will have asizeable impact on the future of lubrication, but a key area that will remain vital regardless is that of grease.

Regarding the WCT, a sensitive wire resistance measurement is made and utilized to determine the amount of copper lost from the wire as the test proceeds. This is a vast improvement over older techniques that rely on a visual assessment of a copper specimen. Then there is the CDT which detects the formation of conductive bridges between tightly spaced conductors while voltage is applied. This is a common situation in electrical systems, such that circuits are in close proximity to each other and they in turn are in contact with either the lubricating fluid or in the vapor phase. Assessing how fluids and grease protect electrical components in such situations is critical. Savant Labs and Tannas Co. recently had these on display at their exhibition at STLE.

Using high performance components and packages for both lubricants and greases that are designed specifically for the EV space provides optimized additive technology that delivers protection for these applications. IPAC 2629C and 2633 are prime examples. These are high-end yellow metal corrosion inhibitors that provide protection for yellow metal, and they do so at elevated temperatures while providing additional EP protection. While IPAC 2633 is an excellent allaround choice for protecting yellow metal, IPAC 2629C is suitable for applications where more active sulfur may be present. This is key because sulfur will likely continue being a key element in providing EP protection, and deleterious effects can be especially mitigated with IPAC 2629C. This class of components finds their way into the driveline segment, and they will become more important as more drivetrains are electrified. IPAC technology in manufacturing these components extends around the globe with production sites currently in North America and Asia. IPAC continues to expand its reach in producing this and related chemistries.

SOURCE | IPAC

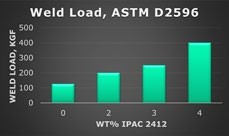

In addition to components for greases, IPAC also offers state-of-the-art packages delivering performance across a wide range of performance areas, including EP, corrosion and friction. One of these is IPAC 2412. This tiered treat rate additive can be used as low as 4% for NLGI GC/LB compliance for many greases without harm to dropping point or other key grease structure deliverables.

Using IPAC 2412 in grease provides key performance without introducing heavy metals such as antimony. It helps the grease maker simplify logistics and inventory by stocking one additive. In addition, IPAC 2412 offers the opportunity to meet the new HPM requirements with the addition of HL in many cases.

IPAC is dedicated to developing the next generation of additives and fluids for the EV market, in a sustainable manner. We believe greases and corrosion inhibitors will be key segments going forward, and supporting these changes with the latest technology and advancement will ensure longer equipment life. The chemistry IPAC delivers to the market is designed to improve efficiency, provide longer fluid life, and reduce degradation of fluids and greases to protect equipment for longer service. .

Visit IPAC today at www.ipac-inc.com.